How Premier Aluminum Llc can Save You Time, Stress, and Money.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Blog Article

The Basic Principles Of Premier Aluminum Llc

Table of ContentsWhat Does Premier Aluminum Llc Do?Get This Report about Premier Aluminum LlcPremier Aluminum Llc for BeginnersThe Buzz on Premier Aluminum Llc

(https://www.openstreetmap.org/user/premieraluminum)Utilizing low cost and unqualified providers can cause quality concerns, and threw away time and money in the long run. To assist you via the process, here are some things to think about when choosing the right steel spreading supplier.

For instance, a business that just utilizes the investment spreading process will attempt to market you on why that process is best for your application. What if making use of the sand spreading process is best for you and your requirements? Instead, try to find a distributor that offers an array of casting processes so the very best alternative for YOU is selected

If collaborating with a solitary source for all of your spreading needs is crucial to you, the supplier requires to be varied in its capacities. When combined with various other integrated capacities, this can aid streamline and press the supply base. When selecting the right spreading vendor, careful consideration should be provided to high quality, solution, and rate.

A Biased View of Premier Aluminum Llc

Buyers increasingly pick spreading distributors that have machining capacities. This can stay clear of conflict if flaws are discovered throughout machining. If a 3rd party is machining, it might lead to "finger-pointing" regarding that is at mistake. Is it a casting issue or a machining problem? If the casting provider uncovers an issue throughout machining, the trouble is solved quicker without any disagreement over whose fault it is.

Problem or no, integrated machining simplifies the supply chain and decreases dealing with time and shipping price prior to the product makes it to the customer. What do you require from your casting provider? Are you searching for someone to simply deliver a metal component to your front door or do you need much more? If you do not have internal metallurgy experience, verify that the supplier can offer guidance in selecting the proper alloy based on your specific application.

Some factories are limited or specialized. Make sure the vendor can meet all your product or alloy demands to remove the demand for multiple distributors.

3 Simple Techniques For Premier Aluminum Llc

Study the distributor's web site. Talk with a sales rep or organization associate. Ask a great deal of concerns. Visit their facility. Get an understanding of what they can do for you and if you can see on your own constructing a solid, shared relationship with them.

Aluminum is likewise light-weight and has excellent corrosion resistance, making it suitable for applications where weight and longevity are necessary factors. In addition, aluminum casting is a cost-efficient approach of production, as it calls for less energy and sources than other methods. Iron spreading, on the various other hand, involves putting liquified iron into a mold to develop a preferred form.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Iron casting is likewise able to stand up to heats, making it appropriate for use in applications such as engine parts and industrial machinery. Iron casting can be more expensive than aluminum casting due to the higher price of raw products and the energy needed to thaw the iron. When deciding between light weight aluminum spreading and iron spreading, it is very important to take his response into consideration the details needs of the application.

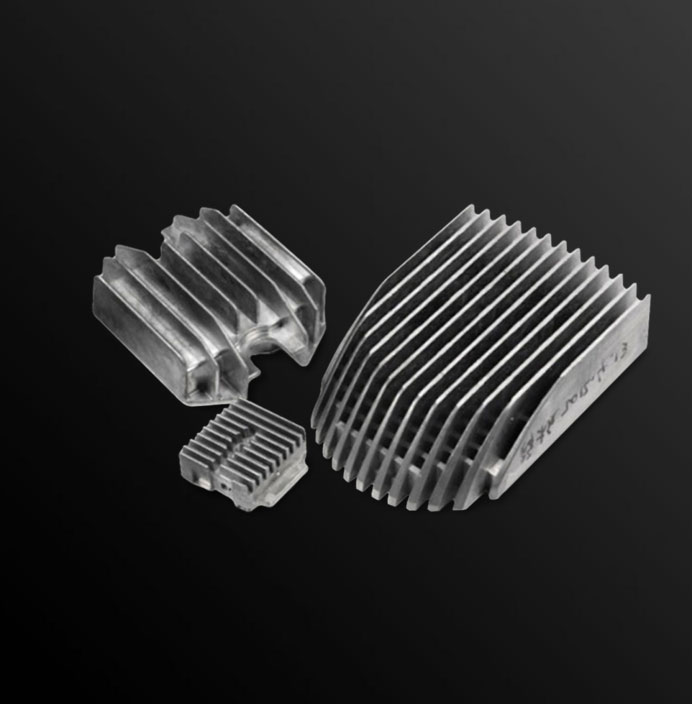

In conclusion, both light weight aluminum casting and iron casting have their own distinct benefits and disadvantages. There are 3 sub-processes that fall under the category of die spreading: gravity pass away spreading (or irreversible mold and mildew spreading), low-pressure die spreading and high-pressure die spreading. To obtain to the finished product, there are three key alloys made use of as die spreading product to select from: zinc, light weight aluminum and magnesium. Report this page